Wire rope cutter 8320-200 JL with cutting plate

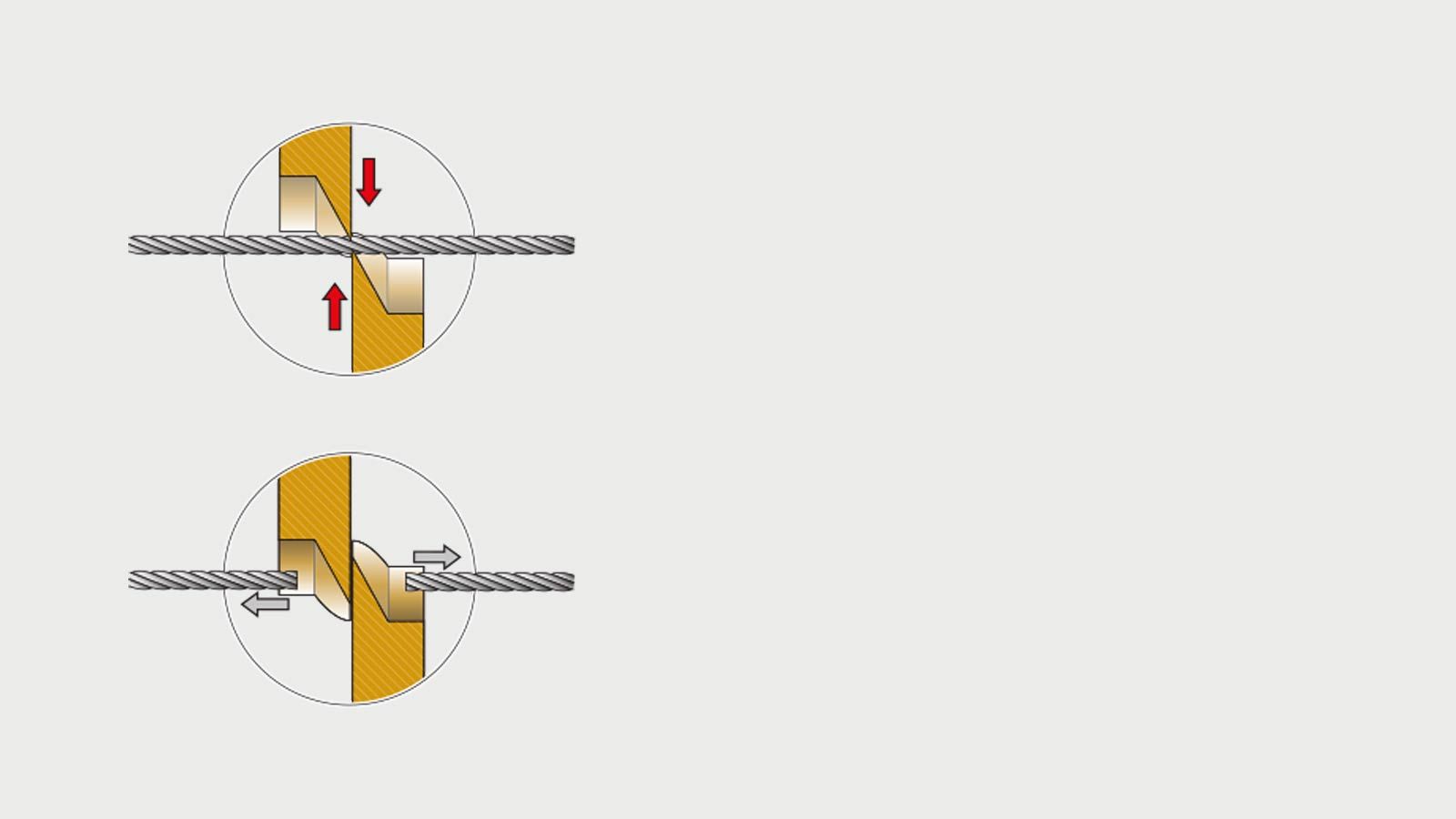

Wire rope cutter with shearing cut technique

Strong cutting Clean cuts Simply perfect

At last, the fanning out, or separation, of the ends of wire ropes when cutting them is a thing of the past. That's because thanks to its clever shearing cut technique, our wire rope cutter 8320-200 JL with cutting plates cuts wire ropes safely and quickly. Little effort is required to operate the innovative construction with the exchangeable plates, which is ideal for wire up to 750 N/mm² and wire ropes to 1800 N/mm².

- Easy-to-change cutting plates

- Two integrated press profiles for Bowden cable terminal sleeves and cable end sleeves

- Latch to prevent unwanted opening

- Low force needed due to the optimum cutting-edge geometry

- Long service lives

- High cutting performance

Splicing

The old seafaring ability to separate the rope into its individual strands so as to then braid them into a loop or lengthen the rope with another rope without knotting.

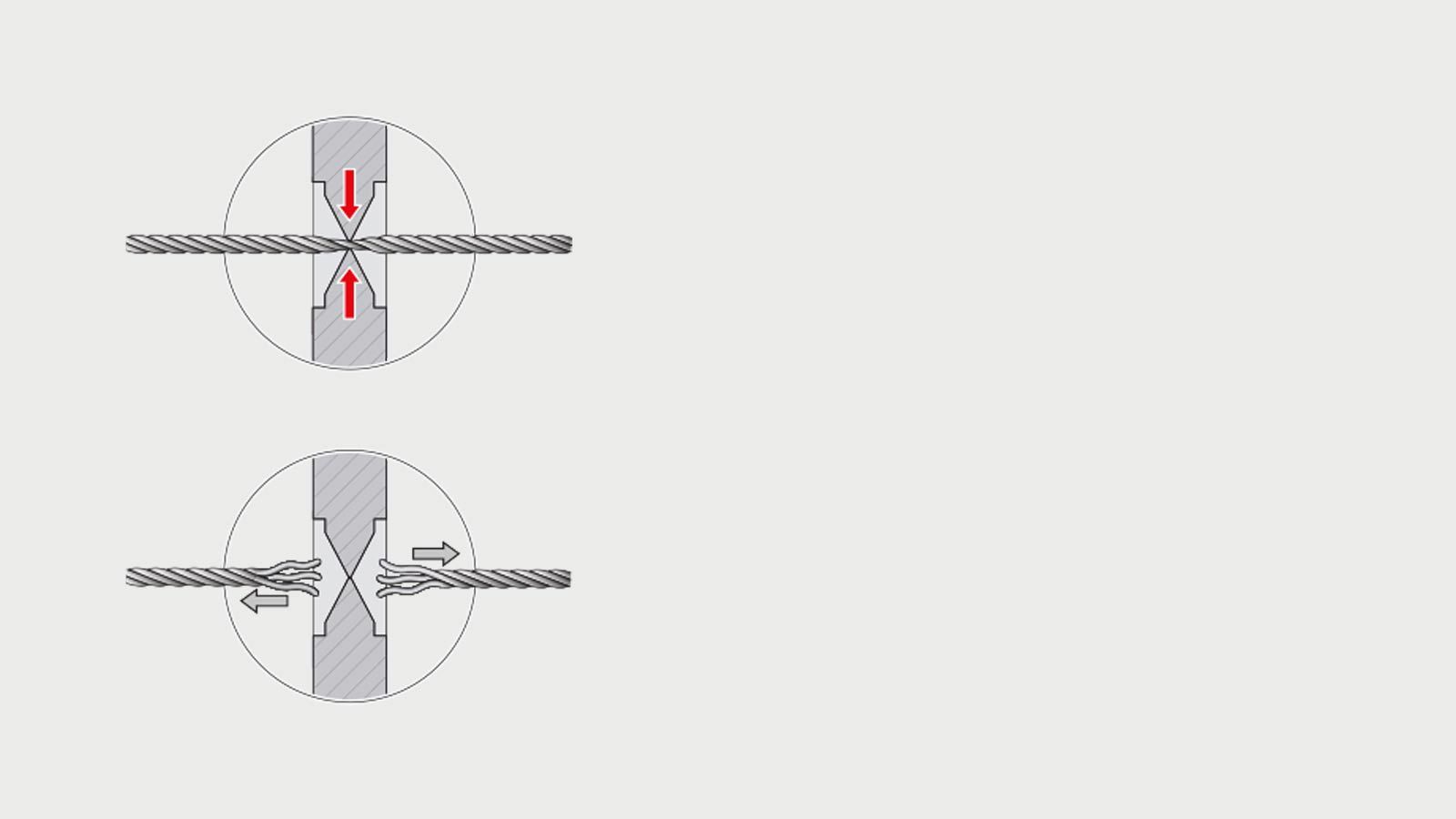

Fanning out

Fanning out - that is separating off into individual strands - is not wanted when cutting wire ropes. It is a very laborious business to splice wire ropes. That is why more up-to-date ways are available to incorporate loops in wire ropes. However, they require a smooth cut without any spliced strands.