Alu-Dremometer universal torque wrench

Unbeatable classic – for more than 50 years

For universal use Strong and reliable The original

For more than 50 years, our Alu-Dremometer has guaranteed controlled and safe screw tightening in almost any installation situation – regardless of where you apply the force. The user-friendly design prevents unintentional adjustment of the torque figure. Maximum precision, durability and reliability – even with high constant use – are the trademarks of our classic.

- Excellent design for safe, fault-free use

- Easy, user-friendly torque adjustment for reliable working

- Non-losable hexagon key in the handgrip

- Strong, high-strength yet light, long-lasting aluminium alloy

Operates without inaccuracies

Thanks to the unique single-axis location of the centre of rotation and the output square drive

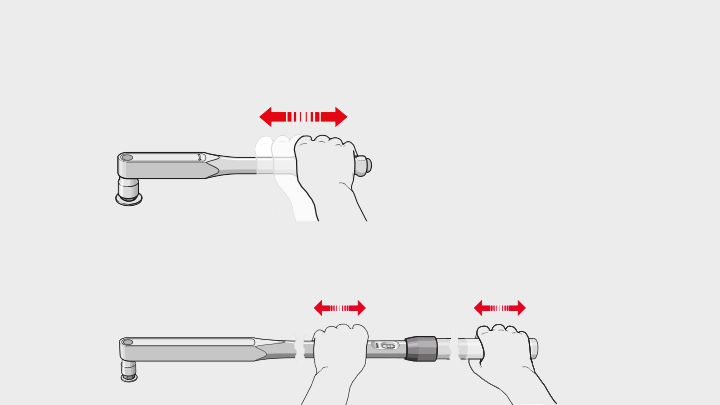

Wherever you apply the force, whether in the middle of the handle or elsewhere on the DREMOMETER, with both hands or using an extension tube, the torque setting is always attained – with no shifts in values. Thanks to the unique single-axis location of the centre of rotation and the output square drive, the DREMOMETER is a tool that can be used without errors. Unlike other torque wrenches, this single lever facilitates tightening without shifts of the measured value and without interference caused by activation outside of the handgrip.

However, value shifts are possible when activating the DREMOMETER with special wrenches or when using wrenches with different depth gauges.

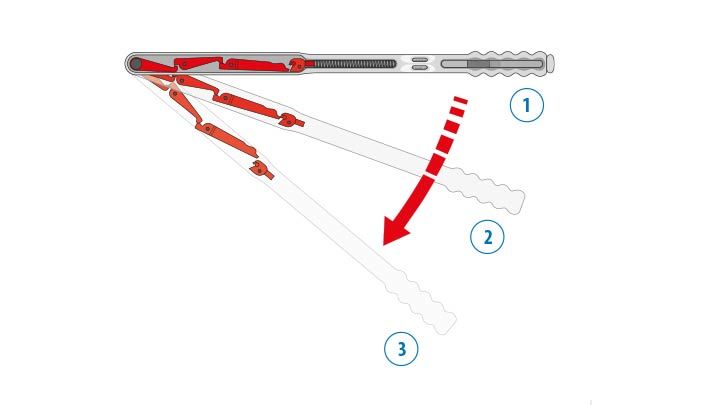

Principle of function of the Dremometer

Long-term precision

The lever chain, which is produced in the group's own quality drop forge, reduces the load on the mechanism to the minimum. The optimally matched dimensions of the individual levers are what give the DREMOMETER its unique precision and make it so long-lasting.

(1) Position of the lever chain without impact of force (in starting position).

(2) Position of the lever chain with impact of force before the set torque is achieved. The force is transferred from the primary lever to the intermediary and final lever until the final lever slips past the so-called release lever through the sliding back of the angle-lever body.

(3) Position of the lever chain with impact of force after the set torque is achieved. Direct position after the "click" that is distinctly heard and felt. The lever chain returns to the basic position (1) when the load is removed.

Technology

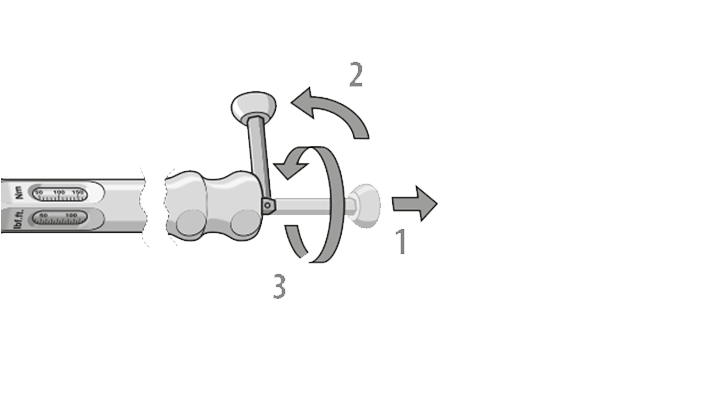

Setting the torque on the Dremometer

Setting the torque to N·m or lbf·in /lbf·ft using the non-losable hexagon key in the handgrip. The smooth-running mechanism enables the setting to be made quickly without significant force needing to be applied.

All the benefits at a single glance

Square drive

In the DREMOMETER, the output square drive and the pivot point of the primary lever are situated on a single axis.

Advantage: The absolute precision is always maintained. Even if the tool is operated outside the handgrip or with an extension pipe.

This ensures a high degree of user safety; can be extended to reduce the user's working load.

Lever chain

The integrated lever chain reduces the strain on the measuring mechanics to a minimum, which means that the measuring mechanics can be constructed with much greater sensitivity.

Advantage: High precision and a long lifetime.

Extremely low wear and long service life

Double square drive

On request, our DREMOMETER (except type F) can be provided with a double square drive. Separate ratchet heads are also available for almost all models (except type F).

Advantage: Controlled counter-clockwise tightening and working in very narrow spaces are possible without any problems.

Scale

Two scales on each DREMOMETER indicate N·m and the common US unit of torque measurement (apart from types E - F).

Advantage: Exact reading even in lbf·in or lbf·ft. Easy operation - fast and safe torque tightening

Handgrip

The nice-to-hold handgrip enables safe work and less operator fatigue. The full-metal construction makes DREMOMETER models particularly robust.

Advantage: High level of dependability even under tough continuous use

Test certificate

All DREMOMETER models come with a test certificate to DIN EN ISO 6789:2003.

Advantage: guaranteed precision of ± 3% on the scale set torque. The specifications of the standard (± 4 %) are exceeded.